The world is facing chronic water risks with the demand-supply gap increasing at an alarming pace. The industry is an important stakeholder in water resource management and as a responsible member of the community, needs to be proactive in combating water risks.

Our objective, at CII Water Institute, is to facilitate the industry in their endeavor to achieve water efficiency through comprehensive water audits across different sectors. Water audits act as an instrument to identify areas of higher specific water use, assess wastewater pollutant load and determine techniques for mitigation through the application of 3R (Reduce, Reuse, and Recycle) principle. Through our water audit services, we have guided the industry in deciding feasible options on reducing water usage, minimizing wastewater generation, and maximizing recovery. CII's water audit provide greater water efficiency solutions and cost savings for meeting internal policies, complying with legal obligations or demonstrating a commitment to sustainability.

The water audits follow a multi-staged approach in order to provide both short-term and long-term sustainable water management solutions. The Institute’s experienced teams include analytical, design and engineering experts to work through the audit process and examine solutions for better water management.

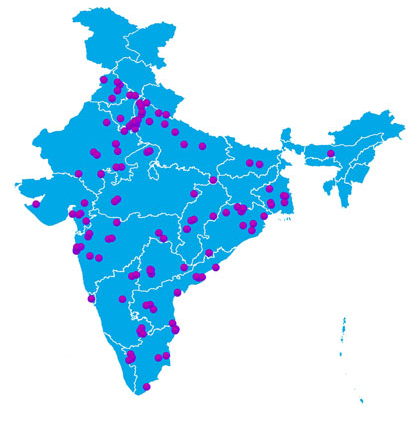

The potential annual water savings from the 200+ water audits undertaken by the Institute till date are estimated at about 160 billion litres, equivalent to supplying freshwater to entire rural population of India for two days

Major benefits of water audits across the industrial sectors:

Water Audit is a systematic process of objectively obtaining a water balance by measuring the flow of water from the site of water withdrawal or treatment through the water distribution system and into areas where it is used and finally discharged. The various steps followed during the course of a Detailed Water Audit are as follows:

❯ A Preliminary Water Survey (PWS)/reconnaissance surveys conducted before initiating the Detailed Water Audit (DWA). This helps in identifying specific areas to be included in Scope of Work.

❯ The Institute customizes Detailed Water Audit agreement to efficiently meet client needs, schedules, and defined scope.

❯ A last mile discipline approach is followed.

❯ State of the art instruments and portable water quality testing kits are used for measurement and monitoring.

❯ Water Mapping and comprehensive water balances.

❯ Water quality assessments.

❯ Recommendations and identification of strategies.

❯ Training programs organized for sensitizing the plant personnel,

operators and employees raising awareness.

The grouping is based on the Ministry of Environment, Forest and Climate Change (MoEFCC) criteria of categorization of industrial sectors based on the Pollution Index which is a function of the emissions (air pollutants), effluents (water pollutants), hazardous wastes generated and consumption of resources.

Category I: Chlor Alkali, Fertilizer, Ferrous & Nonferrous (Integrated Plants), Pulp & Paper, Textiles, Petrochemical, Oil Refineries

Category II: Automobile, Power, Cement, Sugar, Paint, Airport, Hotels (Large), Pharmaceutical, Distilleries (Alcoholic beverages), Mines

Category III: Engineering, Cigarette, Buildings, Food and Food Processing, FMCG, Tyre Manufacturing, Potable Alcohol Blending,

Non-Alcoholic Beverages (soft drinks)